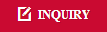

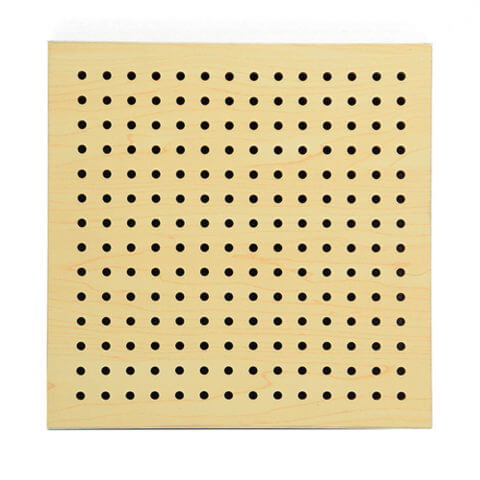

Micro Perforated Panel Micro Hole Acoustic Panel Perforated Wood Board

Micro perforated panel is kind of wooden sound acoustic panels with holes on both front and back sides. Micro perforated MDF board not only has good sound absorbing effect, but also looks great visually. Compared to bigger holes wooden perforated panel, micro hole acoustic panel is harder to make and is better at absorbing low frequencies sound.

Micro Perforated Wood Panels Specifications

1.Structure Basic Material, Finish & Back Finish

2.Basic Material E1 MDF, FR MDF, MGO Combination Board etc.

3.Front Finish Melamine

4.Back Finish Black Acoustic Felt

5.Standard Size 600 * 600, 1200 * 600, 1200 * 1200, 2440 * 1200 mm, etc.

6.Standard Thickness 12 / 15 / 18 mm perforated wall panel

7.Standard Pattern 8 / 8 / 2, etc.

8.Acoustic Principle Resonance Absorption

9.Fire rate Can meet China Standard Class B1 and BS476 Part 7 Class 1

10.Eco Level Perforated wood wall panels can meet China and EU Standard Class E1

Micro Acoustic Board Panels Sound Coefficient:

The sound absorption coefficient is in accordance with the sound-absorbing material classification.

Wooden Perforated Acoustic Panel Installation:

1.Installation System one (with gap)

2.Installation System two (without gap)

Packing:

Our perforated acoustic panel acoustic board is usually packaged in cartons. Pallet is available by the customer request with additional cost.

Application:

There are many kinds of projects, such as Melbourne Airport, Australia Bundoora Church Back Side, Guangzhou opera, KFC, Wanda, Suining Hotel, etc.

Our Services

1. We are very glad that the customer offers us suggestions on price and products.

2. We will sincerely provide the best service and production for you.

3. The material of our micro hole acoustic panel products are mostly made in China.

4. Our products have been exported to US, UK, Australia, Singapore and other countries and regions.

5. Elegant design, reliable quality control, and short delivery let us have high reputation from our clients.