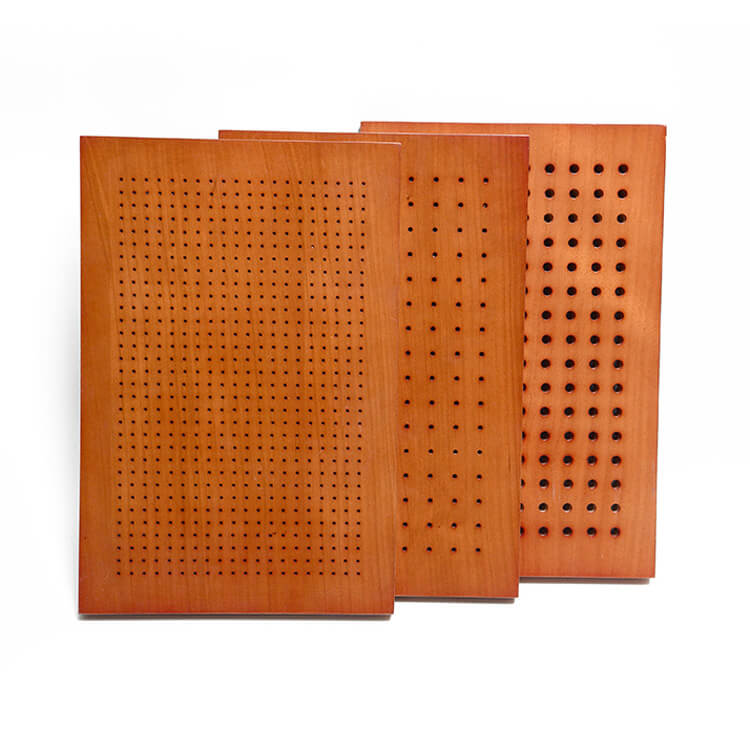

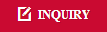

Wooden Perforated Acoustic Panel Wood Perforated MDF Wall Panel

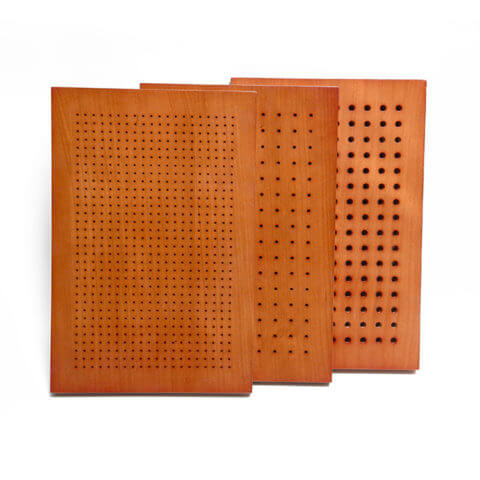

Wooden perforated acoustic panel is kind of wooden acoustic panel with holes on both front and back sides. Perforated decorative MDF panels with bigger holes are direct perforation, while panels with micro holes are big and small hole, which mean small holes on the visible side and the big holes on the back side.

Perforated Acoustic Panels Specifications

1.Structure Basic Material, Finish & Back Finish

2.Basic Material E1 MDF, flame retardant MDF, normal MDF

3.Front Finish Melamine

4.Back Finish Black Acoustic fleece

5.Standard Size 600 * 600, 1200 * 600, 1200 * 1200, 2440 * 1200 mm, etc.

6.Standard Thickness 12 / 15 / 18 mm perforated MDF

7.Standard Pattern 8 / 8 / 1, 16 / 16 / 3, 16 / 16 / 6, 32 / 32 / 6, 32 / 32 / 8. etc.

8.Acoustic Principle Resonance Absorption

9.Fire rate Perforated MDF panels can meet China Standard Class B1 and BS476 Part 7 Class 1

10.Eco Level MDF perforated panel can meet China and EU Standard Class E1

Standard acoustic perforated MDF board pattern:16-6, 32-8 and the Sound Absorption Frequency Characteristic Graph

Installing Method of Wall Perforated Wood Acoustic Panels:

*Measure the wall size, confirm the installation location, determine the horizontal and vertical lines, determine the wire, pipe and other objects’reservation cutting size.

*Calculate and cut part of the sound absorption perforated panels according to the actual size of the construction site and lines, and set aside for the wire, pipe and other objects.

*Install keel: Use the nail to fix the wood keel / light steel keel to the building wall. The nail must be embedded more than 2/3 into the wood keel / light steel keel, and the nail must be evenly arranged. Fix the keel with screws. And the fix perforated MDF wall panel on keel.